Designing a great product requires understanding every step of the development process. We have that understanding.

Years of practical molding experience using every blow moldable material allows us to recommend compounds to meet special demands. We can provide plastic testing and laboratory-analysis services when your products require special materials-analysis data. We offer a variety of recycled material options.

We pioneered systems that label, weld, insert, punch, slice and finish parts in-mold and we developed advanced heat extraction methods for faster production cycles. We apply this knowledge to every project.

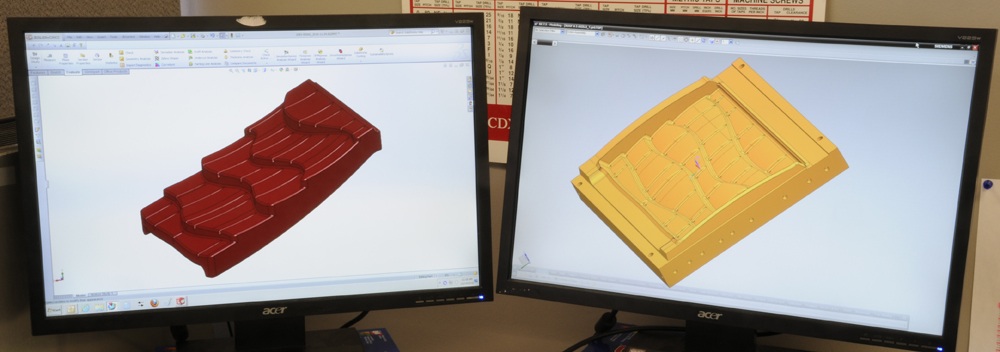

Predictive modeling helps us assure your products meet all specifications and regulations. When there is a need, we offer a variety of prototype options.

To finish your product, you can choose from a complete range of services, secondary operations, decorating techniques, assembly, pack-out, storage and shipping options.

Our design team will provide you with a complete package at a value that can’t be beat. Please contact us today!